Highly diverse machine facilities connected simply and digitally – Episode 3: Pallet machine

Higher numbers of variants and smaller batch sizes are forcing companies to make production more flexible and more agile. This is particularly difficult to achieve with “brownfield” plants if the machines involved were not designed to be used flexibly in a Smart Factory environment (a.k.a. Industry 4.0). This requires the ISA-95 stack to be upgraded to a digital production platform. In SAP, FORCAM has found a partner for enabling brownfield plants to be connected using the FORCE EDGE CONNECT connectivity layer, regardless of vintage, and linked to the SAP digital production platform – without having to replace machinery or equipment.

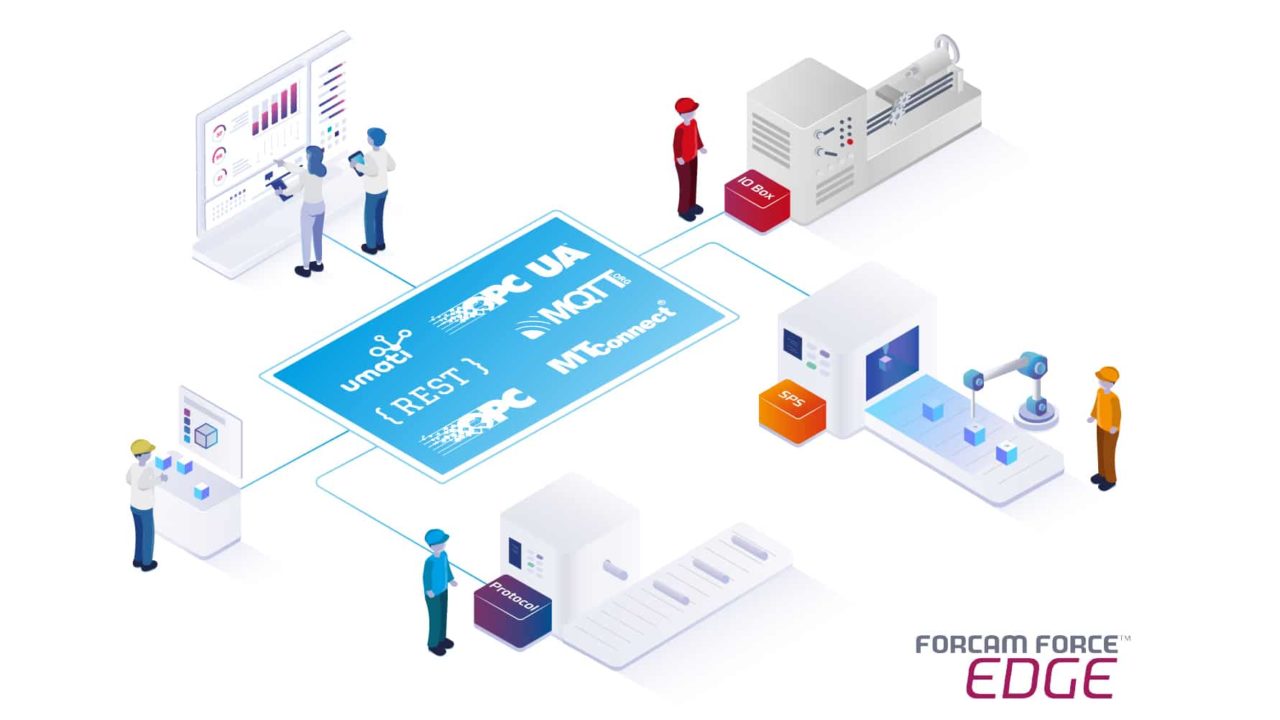

In six articles for common machine types, we outline how companies can use the FORCE EDGE CONNECT connectivity layer to connect all machines – regardless of manufacturer, vintage or control system – and process the data for example in the SAP DMC (Digital Manufacturing Cloud) or SAP ME/MII.

Episode 3: Pallet machine

In the manufacturing industry, many machines involve the use of pallets. These “pallet machines” must be considered separately in data-driven manufacturing, because they are usually running several active operations at once.

One characteristic feature of this type of machine is that several pallets are present and are processed actively in the machine at different times. This is the case, say, with machines that feature a separate setup pallet. This means that one pallet is actively processed in the machine while the other is put through a process of preparation. As a result, several operations are running on this machine at the same time, each with a different work status – for example, in production or in setup.

Reference machine, plug-ins, work process, target architecture

- Reference machine

When selecting the reference machine, one should ask how many pallets this machine has. The main focus is on the preparation of operations on carrier pallets.

- Plug-ins

When selecting the machine-relevant plug-ins, the question arises about network-compatible control systems for tapping signals or transferring NC programs.

- Work process

When analyzing a company-specific work process at the pallet machine, the main focus is on the trigger signals. These requirements are mapped onto the FORCAM solution portfolio.

- Architecture

The data-driven architecture for machine connectivity involves the plant or the network-capable control system delivering signals / information via the FORCAM FORCE™ plug-ins to the “FORCE EDGE CONNECT Machine Connectivity and Model” module.

There, the machine signals are assigned to a corresponding semantic. The machine signals and associated semantics are forwarded to an interfaced system, for example the SAP DMC (Digital Manufacturing Cloud) or SAP ME/MII, in the form of harmonized and standardized machine events.

Autor: Marc Fröschl (Product Owner)

Foto: Hermle AG – www.hermle.de

Your contact person

You want to learn more about the topic? As your contact person, I will be happy to answer any open questions you may have about our solutions. You can reach me at: Oliver.Hoffmann@forcam.com