Five reasons for SMEs to manufacture digitally via the cloud

The digitalization of manufacturing brings enormous efficiency and competitive advantages. In particular, small and medium-sized enterprises (SMEs) need a simple, quick-to-use, and cost-effective solution for this. This is what the concept of “Software as a Service” (SaaS) offers.

Cloud computing enables industrial SMEs to significantly optimize their products through the Internet and the cloud resources behind it and create a cost-effective alternative to on-premise systems. Five good reasons speak for using a SAAS solution, especially for SMEs.

1. Cost-conscious complete solution without own additional resources

With FORCE MES LITE (Software as a Service), companies receive a Smart Factory as a cost-conscious complete solution: they can start their digital products in just a few days. With a standardized SaaS solution, SMEs quickly create transparency in production, the basis for efficiency increases. IT operations and service & support are outsourced. There is no need to build additional in-house IT resources for personnel or materials.

The FORCE MES LITE solution is cost-conscious because companies can budget with a transparent monthly fixed price. This creates planning security. Costs for maintenance, repairs, and updates are included in the subscription price; there is no up-front investment for setting up the solution.

2. Higher efficiency through real-time analyses – service, support, and updates are included

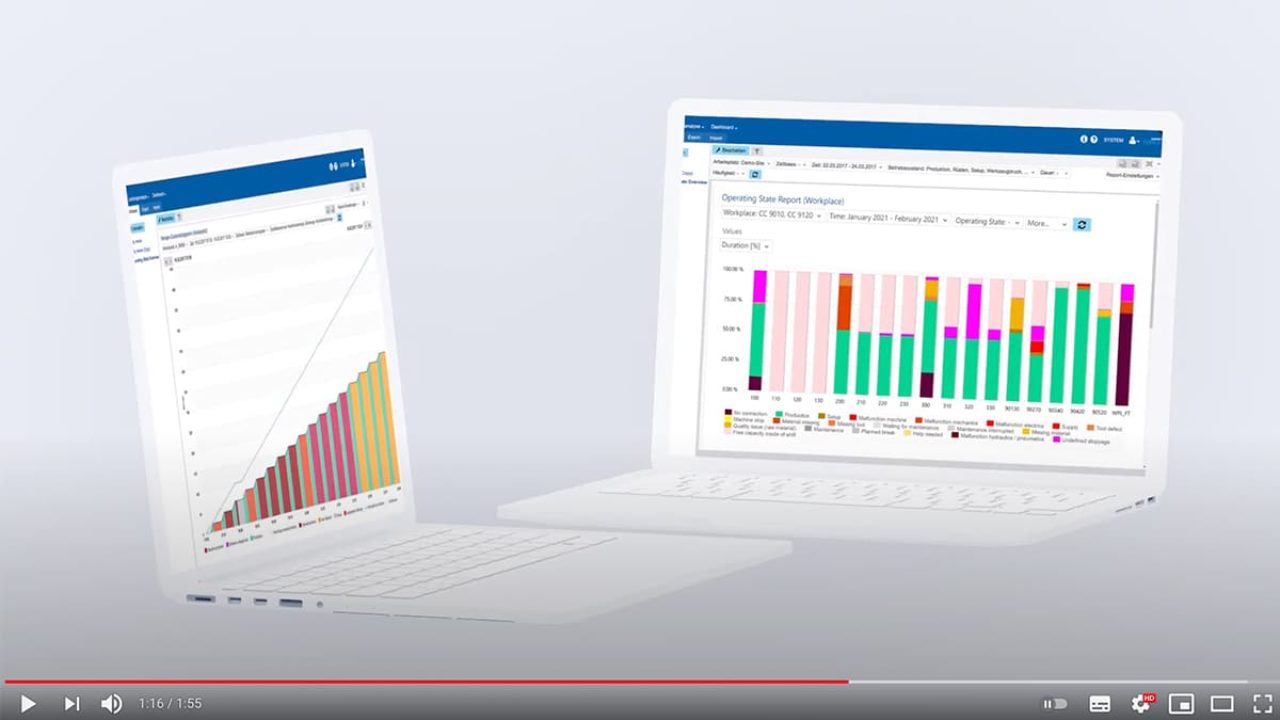

After the standardized digital connection of the machines to a central platform, the factory teams can analyze all performance statuses with precise critical figures from the cloud in real-time – at any time on any computer. In this way, they increase efficiency and productivity independently and sustainably.

The standardized SaaS solution offers the following data flow: it collects the signals from a wide range of machines, converts them into usable data, and sends them to the software in the cloud. From there, factory teams receive user-friendly evaluations on their screens – on a central dashboard and all desired end devices.

3. Installation in a few days

With the FORCE MES LITE solution, companies can launch their Smart Factory in just a few days. The software is available via the Internet, and the required hardware arrives by post. SMEs can carry out the installation themselves and start digital production after a few days.

The hardware is manageable. First, it includes a FORCAM I/O controller, which collects the machine signals and converts them into network information. This information is transmitted to another device – the so-called edge gateway – for further processing in the cloud. The edge gateway forms the central interface between manufacturing and the cloud.

4. Security and stability through established cloud providers

The safety and stability of a SaaS operations should be critical decision criteria for companies considering a SaaS offering. For its SaaS offering, FORCAM works with leading cloud providers such as Microsoft Azure to provide its customers with the highest level of security. Access to the cloud is provided exclusively via encrypted connections.

5. Flexible also in the future

In the FORCE MES LITE solution, the desired functions can be selected and expanded in a modular fashion from predefined application scenarios. Typical applications are machine data and production data acquisition (MDE/BDE) and vital critical figures such as overall equipment effectiveness (OEE).

With the modular SaaS solution, SMEs will also remain flexible in the future; companies can easily integrate additional functions and applications later if necessary.

Author: Maurice Fackel, Business Development Manager bei FORCAM

Your contact person

Do you want to know more about this topic? As your contact person, I will be happy to answer any open questions you may have about our solutions. You can reach me at: Siegfried.Maigler@forcam.com