none

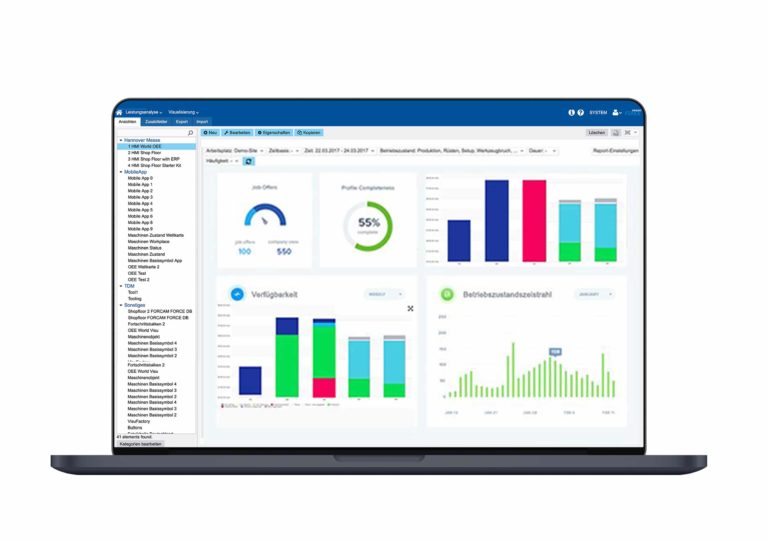

Visualization and Reporting

Analyze virtually –optimize in real-time

If value creation is to increase, machine and plant downtimes must be reduced, and their availability increased. But: Which technology reports faults in the machines at an early stage? How can waste be minimized sustainably? Answer: through precise real-time data from the factory.

The FORCAM application Performance Analysis collects critical data in production and prepares it in reports for meaningful information. Both real-time production statuses and historical analyses are visualized.

This allows you to precisely assess the manufacturing processes at any time to derive the right measures. Alarm functions notify you immediately in case of bottlenecks or malfunctions -via email or push notification on the smartphone.

Your added value

- Accurate evaluations to the second in clear dashboards and reports

- All relevant key figures at a glance

- Daily reports by email

- Benchmarking of different workplaces up to plants

- Direct comparison of operating states and cumulative error reporting

- Permission management for defined user groups